|

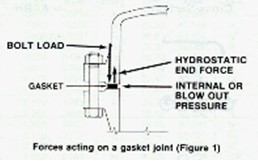

Forces Acting on a Gasketed Joint

|

The

Internal Pressure:

These are the forces continually trying to

unseal a gasketed joint by exerting pressure

against the gasket (blowout pressure) and

against the flanges holding the gasket in

place (hydrostatic end force). See Figure 1 The

Internal Pressure:

These are the forces continually trying to

unseal a gasketed joint by exerting pressure

against the gasket (blowout pressure) and

against the flanges holding the gasket in

place (hydrostatic end force). See Figure 1

The

Flange Load: The total force

compressing the gasket to create a seal,

i.e., the effective pressure resulting from

the bolt loading. The

Flange Load: The total force

compressing the gasket to create a seal,

i.e., the effective pressure resulting from

the bolt loading. |

|

Temperature:

Temperature creates thermo-mechanical

effects, expanding or contracting the metals,

affecting the gasket material by promoting "creep

relaxation" which is a permanent strain or

relaxation quality of many soft materials under

stress.The effect of certain confined fluids may

become increasingly degrading as temperature rises

and attack upon organic gasket materials is

substantially greater than at the ambient

temperatures (about 75°F). As a rule, the higher the

temperature, the more critical becomes the selection

of the proper gasket. Temperature:

Temperature creates thermo-mechanical

effects, expanding or contracting the metals,

affecting the gasket material by promoting "creep

relaxation" which is a permanent strain or

relaxation quality of many soft materials under

stress.The effect of certain confined fluids may

become increasingly degrading as temperature rises

and attack upon organic gasket materials is

substantially greater than at the ambient

temperatures (about 75°F). As a rule, the higher the

temperature, the more critical becomes the selection

of the proper gasket.

Medium:

The liquid or gas against which the gasket is

to seal. Medium:

The liquid or gas against which the gasket is

to seal.

General

Conditions:

The type of flange, the flange surfaces, the type of

bolt material, the spacing and tightness of the

bolts, etc. General

Conditions:

The type of flange, the flange surfaces, the type of

bolt material, the spacing and tightness of the

bolts, etc.

Each of

these factors require consideration before an

effective gasket material is finally chosen.

However, the proper gasket may often be rejected

because failure occurred due to a poorly cleaned

flange face, or improper bolting-up practice. These

details require careful attention, but if complied

with will help eliminate gasket blow-out or failure.

There

are three principal forces acting on any gasketed

joint. They are: Bolt load and/or other means of

applying the initial compressive load that flows the

gasket material into surface imperfections to form a

seal. The hydrostatic end force, that tends to

separate flanges when the system is pressurized.

Internal pressure acting on the portion of the

gasket exposed to internal pressure, tending to blow

the gasket out of the joint and/or to bypass the

gasket under operating conditions. There are other

shock forces that may be created due to sudden

changes in temperature and pressure. Creep

relaxation is another factor that may come into the

picture. There

are three principal forces acting on any gasketed

joint. They are: Bolt load and/or other means of

applying the initial compressive load that flows the

gasket material into surface imperfections to form a

seal. The hydrostatic end force, that tends to

separate flanges when the system is pressurized.

Internal pressure acting on the portion of the

gasket exposed to internal pressure, tending to blow

the gasket out of the joint and/or to bypass the

gasket under operating conditions. There are other

shock forces that may be created due to sudden

changes in temperature and pressure. Creep

relaxation is another factor that may come into the

picture.

Figure

1 indicated the three primary forces acting upon a

gasketed joint which we will consider for this

discussion. The initial compression force applied to

a gasket seating surfaces regardless of operating

condition. Initial compression force must be great

enough to compensate for the total hydrostatic end

force that would be present during operating

conditions. It must be sufficient to maintain a

residual load on the gasket/flange interface. From a

practical standpoint, residual gasket load must be

"X" time internal pressure if a tight joint is to be

maintained. This unknown quantity "X" is what is

known as the "," factor in the ASME unfired pressure

vessel code and will vary depending upon the type of

gasket being used. Actually the "m" value is the

ratio of residual unit stress (bolt load minus

hydrostatic end force) on gasket (psi) to internal

pressure of the system. The larger the number used

for "m," the more conservative the flange design

would be, and the more assurance the designer has of

obtaining a tight joint.

>>The End Figure

1 indicated the three primary forces acting upon a

gasketed joint which we will consider for this

discussion. The initial compression force applied to

a gasket seating surfaces regardless of operating

condition. Initial compression force must be great

enough to compensate for the total hydrostatic end

force that would be present during operating

conditions. It must be sufficient to maintain a

residual load on the gasket/flange interface. From a

practical standpoint, residual gasket load must be

"X" time internal pressure if a tight joint is to be

maintained. This unknown quantity "X" is what is

known as the "," factor in the ASME unfired pressure

vessel code and will vary depending upon the type of

gasket being used. Actually the "m" value is the

ratio of residual unit stress (bolt load minus

hydrostatic end force) on gasket (psi) to internal

pressure of the system. The larger the number used

for "m," the more conservative the flange design

would be, and the more assurance the designer has of

obtaining a tight joint.

>>The End

|